SLA

Stereolithography (SLA)

Stereolithography is a 3D printing or additive manufacturing technology used to produce high-precision prototypes with functional characteristics and colour, transparent or metallic finishes, which can also be used as masters for die casting or for silicone moulds.

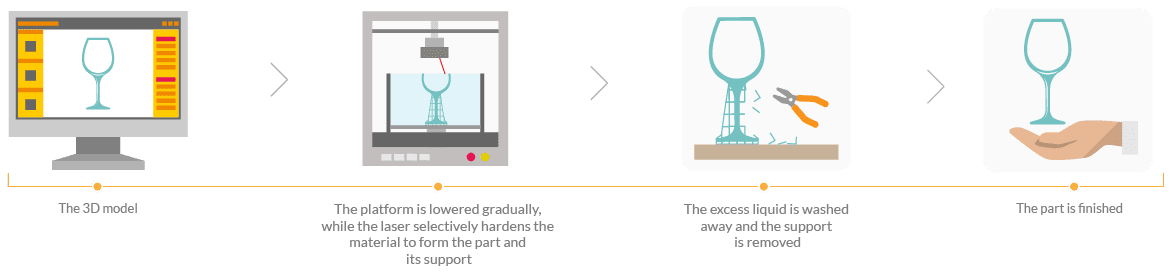

Stereolithography starts by taking a model that is loaded from a virtual 3D file. Using a special programming language, the model is sliced into thin horizontal layers.The support structures are then generated that are needed to correctly attach the part to the machine’s platform.

The stereolithography machine has a tank full of epoxy resin, inside which there is a platform supported on a vertical mechanical axis. Above the tank there is a laser, which is used to polymerise or harden the resin.

In the initial step of the process, a fine layer of resin is exposed above the platform.

The laser beam then traces out the first layer of the model on the surface of the liquid resin, which causes it to polymerise.

After the layer has hardened, the platform is lowered, once again exposing a thin layer of liquid resin on the surface of the tank, ready for the next layer of polymerisation. This process is then repeated, printing layer after layer until the entire three-dimensional object has been formed. The platform is then automatically raised to drain off the excess resin and remove the part. The supports are subsequently removed manually and any traces of liquid are cleaned away. Finally, the surface is further cured in an ultraviolet oven.

Layer thickness

Normal

For highly detailed prototypes and masters. La mejor opción respecto a la relación calidad-precio.

Thickness: 0,150 mm

Thin

For prototypes and masters with an excellent quality. Widely used for transparent parts.

Thickness: 0,100 mm

Ultra thin

For jewellery and similar applications.

Thickness: 0,062 mm

Applications

Rapid 3D Prototyping

Manufacturing aids

Industries that use SLA

Advantages

Large sizes

Large-scale parts are no problem for Pantur, as we are fully equipped to manufacture them. Our group of machines includes one of the largest on the market, which allows us to build parts with a large-scale parts 1500x750x550 mm casing in one piece. However, manufacturing even larger parts is no problem either, as we are experienced in manufacturing them in stages for subsequent assembly.

Rapid and flexible

Offering a rapid, reliable service is one of Pantur’s hallmarks, and we hold ISO 9001:2008 certification for prototype manufacturing and finishing. We have facilities in Sabadell (Barcelona) and Feytiat (Limoges). Our group of machines is large enough to guarantee that we will deliver on time. We can also assign more than one machine to your order,so as to meet the most demanding deadlines.

Professional finishes

At Pantur we know that the difference between a prototype and a great prototype is the finish,which is why we work to ensure our clients have a wide range of finishes available. Pantur offers hand finishes, industrial paint, cosmetic paint, textured paint, metallic paint and many other finishes. We also place our team of professionals with extensive experience in finishes at the service of our clients.

Range of materials

Pantur is proud to offer a wide range of resins, so our clients are sure to find the one that best suits their physical, mechanical or thermal requirements.