Electropolishing is an electrolytic process consisting of immersing the sheets of stainless steel into a bath of sulfuric acid and phosphoric acid at a high temperature.

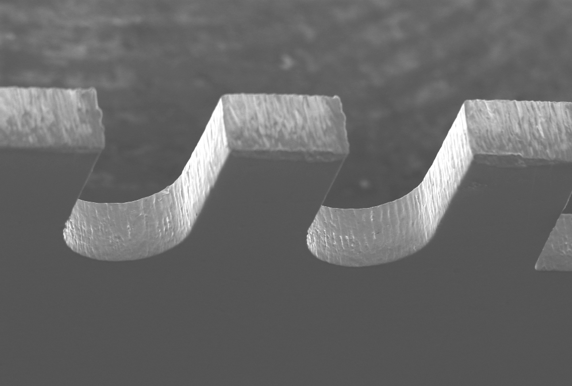

Once submerged, current is applied, equally polishing the surface of the stencil and the internal walls of the SMD pads. This reduces the surface roughness of the material and completely eliminates the roughness and possible burr produced by the micro laser cutting.

The result obtained is similar to the Electroformed Stencils. Recommended for the assembly of Micro BGA’s, Ultrafine Fine-pitch and type 0201 reduced components.

Benefits:

· Eliminates burrs from pad edges.

· Increases printing speed.

· Ratio between deposition volume and pad

volume, close to 1:1

· Reduces cleaning cycles.