Accessories

VarioGrid

Assembly support system. Eliminate the programming time for individual pins for clamping the PCB in the printing line, resulting in higher quality printing as well as high performance, productivity and profitability.

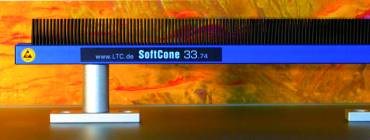

SoftCone

It effectively eliminates interference vibrations on all types of circuit boards that are caused by inserting components into the pick and place. It is ESD compliant and can be magnetically attached.

Squeegees

We manufacture stainless steel squeegees for most screen printing machines on the market, using:

Micro laser cutting (possibility of electropolishing.

Photo etching.

Screen printing tools for prototypes

Manual tool for applying SMD paste on prototype circuits. The system uses a laser-cut prototype lamina for SMD and it offers both the tension and flatness required to correctly apply solder paste.

As part of its constant process of innovation, and in response to the needs of the market, Pantur has developed a manual screen printing tool for creating SMD prototypes. The system uses a laser-cut SMD lamina with optimum tension and flatness for applying solder paste.

Mini Stencils

Tool for reworking, mounting or repairing fine-pitch, BGA or mini-BGA components.

Various stencil models according to requirements.

Mini spatula for applying solder paste.

Reverse engineering

By taking a PCB, photolith film or drawing, we can obtain a gerber file (RS274X) of SMD tracks and pads.

Inspection masks

A mask that allows you to check for the presence of components, for the visual inspection of circuit boards with a high component density. It reduces verification errors and allows for easier control. The masks are manufactured using antistatic material that complies with ESD standards: a laminated conductor, E-glass fibre composite, graphite and epoxy resin with a thickness of 0.2 and 0.5 mm.

Verification of the presence of SMD components after assembly and soldering. It highlights the components, and particularly the small ones, on a black background. It allows you to check the position of the components, and also allows integral control of SMD and standard components.