SLS

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a technique that creates parts from polyamide powder. The result is a strong, flexible and slightly porous material. Of all the 3D printing technologies, this is the one that allows the most freedom of design.

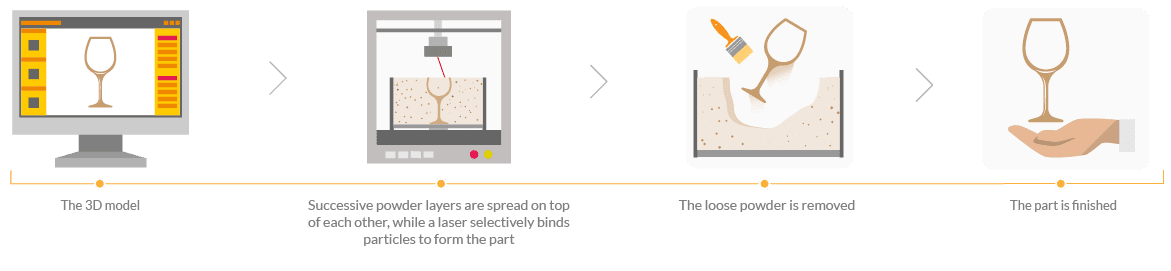

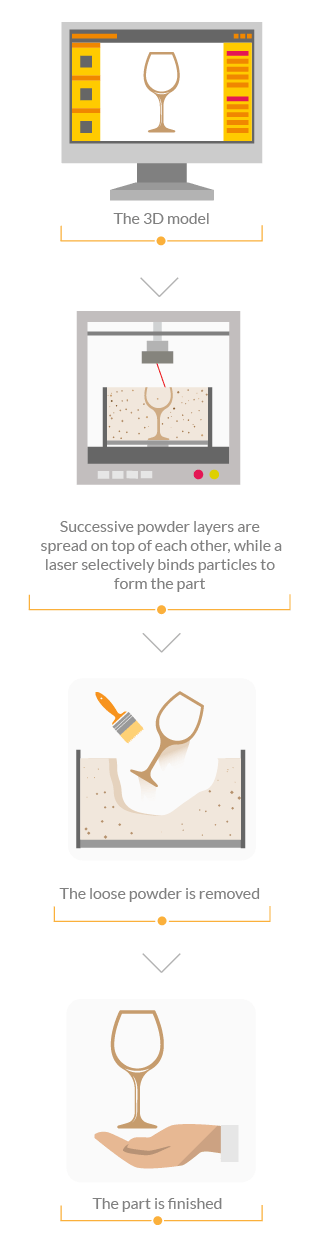

The sintering starts by taking a model that is loaded from a virtual 3D file.The manufacturing process is prepared using specialised programs, by slicing the model into fine horizontal layers.In the initial step of the process, a fine layer of powder is exposed above the platform.

The laser beam then traces out the first layer of the model on the surface of the powder, causing it to sinter. platform is then lowered, exposing another fine layer of powder on the surface of the tank, ready to be sintered. After this the process is repeated, printing layer after layer until the entire three-dimensional object has been formed. This result is a block of powder with the models contained inside. After the block has cooled, the parts can be extracted manually from the polyamide block, before being sanded to yield a completely clean surface.

Applications

Functional prototypes

Production parts

Fuel tanks

Architectural models

Supports

Industries that use SLS

Advantages

Freedom of design

SLS technology gives you freedom of design, as it lets you create models with complex features, negative moulds and details of inaccessible areas. And all of this is simple when you use SLS to create prototypes and production parts.

Functional parts

The SLS process results in functional parts that are durable, and heat and chemical resistant. These parts can be easily connected either mechanically or with adhesives. Secondary operations may include sealants, coatings and metallisation through vapour deposition or electroplating processes. To get the most out of SLS technology, parts should be specifically designed for the process to make full use of the unique benefits of additive layer manufacturing. Your design efforts can now focus on functionality, allowing for more robust designs with fewer restrictions.

Professional finishes

At Pantur we know that the difference between a prototype and a great prototype is the finish, which is why we work to ensure our clients have a wide range of finishes available. Pantur offers hand finishes, industrial paint, cosmetic paint, textured paint, metallic paint and many other finishes. We also place our team of professionals with extensive experience in finishes at the service of our clients.