Due to our speed and flexibility, we are the best alternative to mould or CNC manufacturing for the production of small series.

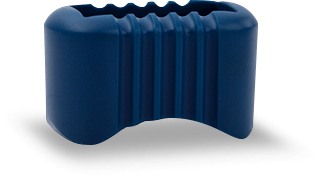

End Pieces and Short Runs

Uses and applications

Introduction to the market

The success of a product is also determined by the speed with which it reaches the market. Additive manufacturing allows parts to be manufactured with final materials (ABS, PC, PCABS, Nylon, ULTEM and others) and professional finishes in just a few days. In this way, pieces can be supplied before mass production is complete.

Market evaluation

If final parts are manufactured using injection molding, any major design modification entails the manufacture of a new mold, or a major modification. Time and cost requirements are high for such modifications. Additive manufacturing allows total freedom in the design of new parts without obligation to use injection molding.

When to choose the Final Parts?

Testing of new designs without mold making.

Fast marketing of final parts.

Real evaluation of a part before manufacturing.

Carrying out market research tests.

Flexible and short series production.

Industries

Discover our range of finishes for end pieces and short runs

Discover our materials for end pieces and short runs